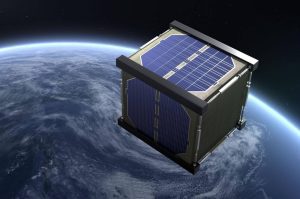

On November 5, 2024, a groundbreaking satellite—LignoSat—was successfully launched into space from NASA’s Kennedy Space Center in Florida, USA, aboard a SpaceX rocket. This collaborative project between Kyoto University and the Japan Aerospace Exploration Agency (JAXA) marks a crucial step in exploring wood as a sustainable alternative to metal materials in satellite manufacturing.

Technical Background and Core Mission

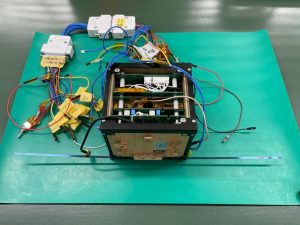

The core mission of the LignoSat project is to explore the durability and application potential of wood in the extreme environment of space, with the aim of reducing space debris. Designed to orbit Earth for six months, LignoSat will face harsh challenges such as cosmic radiation, extreme temperature fluctuations (-170°C to +200°C), and microgravity. Equipped with high-precision sensors and monitoring systems, LignoSat will collect real-time data on the structural changes, mechanical properties, and thermal stability of wood in the space environment, providing scientific evidence for future satellite manufacturing using wood.

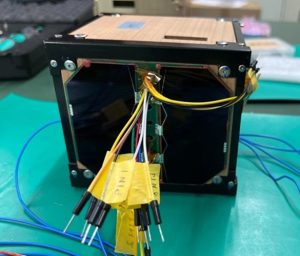

Material Selection and Technological Innovation

The panels of LignoSat are crafted from specially selected magnolia wood, renowned for its excellent strength and toughness in traditional Japanese crafts. More importantly, through an ancient Japanese woodworking technique known as “mortise and tenon,” the various parts of the satellite are ingeniously connected without the use of screws or glue. This design not only reduces the weight of the satellite (just 900 grams) but also significantly enhances its structural stability, ensuring reliable operation under extreme conditions.

Unique Solution to the Space Debris Problem

With the increasing frequency of space activities, the issue of space debris has become increasingly severe. Traditional satellite metal components often fail to completely burn up upon re-entry into the atmosphere, becoming potential orbital hazards. The innovation of LignoSat lies in its use of biodegradable wood as the primary material. This design ensures that the satellite will completely combust upon completing its mission and re-entering the atmosphere, leaving no debris behind, thereby effectively reducing the long-term impact of space debris and potential threats to orbiting spacecraft.

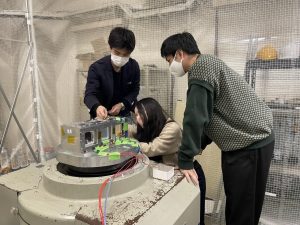

Distinctive Design and Manufacturing Process

The uniqueness of LignoSat’s design is further reflected in its compact size (only 10 centimeters) and lightweight material selection. Through precise calculations and optimized structural design, the research team has successfully kept the satellite’s weight to a minimum. Additionally, the application of the mortise and tenon structure not only enhances the satellite’s durability but also reduces the environmental impact during the manufacturing process, embodying the design concept of a green spacecraft.

Space Testing and Future Prospects

Once in orbit, LignoSat will undergo a series of rigorous tests to validate the actual performance of magnolia wood in the space environment. Researchers will closely monitor indicators such as the structural integrity, toughness changes, and thermal stability of the wood, and conduct comparative analysis with traditional metal materials. These valuable data will provide strong support for the adoption of sustainable materials in future spacecraft.

In conclusion, LignoSat, as the world’s first wooden satellite, not only demonstrates the power of technological innovation but also points the way for sustainable space exploration. With further research and technological advancements, sustainable materials like wood are expected to play an increasingly important role in the aerospace field, offering more environmentally friendly and efficient solutions for human exploration of the universe.